Sales hotline

Sales Department 1: 0531-87885729 Manager Wang 15662708359 QQ: 1344074725

Manager Yin 0531-87886769 15064183919

Sales Department 2: 0531-87869013 Manager Han 15564105123 QQ: 2929008953

Manager Ma 15562572670

Manager Yin 15165067069

Sales Department 3: 0531-87869919

Fax: 0531-87853671

Website:Www.sdalcoa.com

Chengye Plate explains to you:

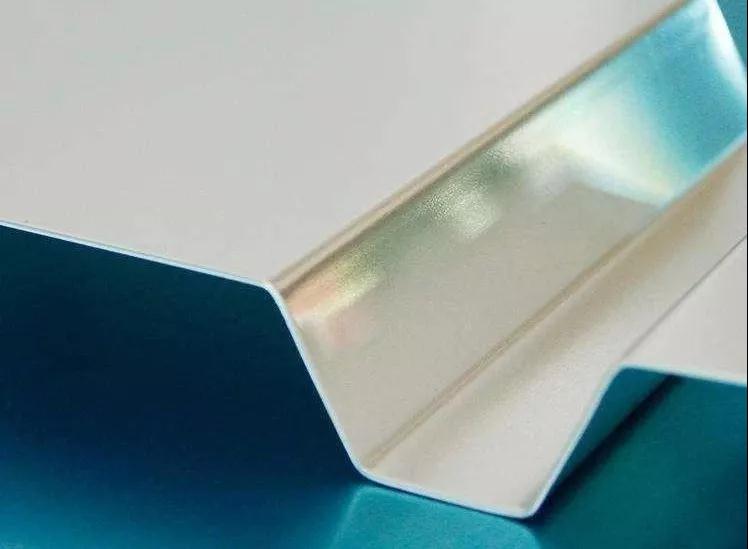

Several main reasons and precautions for cracking of aluminum plates after bending:

1. Hardness of aluminum plate

Aluminum plates have high hardness and are prone to cracking. This requires selecting high-quality aluminum plates, mainly based on their alloy and condition. Usually, the comparison between the 1 series, 3 series, and 5 series is commonly used. The hardness of the 6 series and 7 series is too high, and they need to be annealed to the O state before bending. And also the quality of the aluminum plate.

2. The thickness of the aluminum plate.

It is difficult to bend aluminum plates that are too thick. We can understand immediately and try to use thinner aluminum plates as much as possible.

3. The size of the bent R-angle

The larger the bending R angle, the higher the success rate, so try to increase the bending R angle as much as possible.

4. Aluminum plate texture direction.

The bending direction should be perpendicular to the grain direction of the aluminum plate and not parallel.

For aluminum sheet parts that require wire drawing, it is best to bend them before drawing them if the process allows, otherwise it will increase the probability of bending cracking.

Firstly, the state is the most important

The state is divided into fully hard, semi hard, and soft states (usually referred to as O state). The bending effect of fully hard aluminum plates is not very good (aluminum plates in H18, H19, H38, etc. are all fully hard), while aluminum plates in semi hard state can be basically bent (H24 is also semi hard). The bending of the O state is definitely not a problem, but due to its softness, it is relatively rare to use this state for bending.

Secondly, do you want to choose pure aluminum or alloy aluminum

The hardness of pure aluminum is not very high, and it can be used with 1100, 1050, 1060, etc. It is recommended to use alloy aluminum with 1100 H26 for better hardness, which can be used with semi hard states such as 3003, 3005, 5052, etc.

It is recommended to determine the specific situation of the sample again. If 6061, 2024, or 7075 are used due to their high hardness, especially in T6 state, they should not be bent unless heated and then bent. The difference between high-quality aluminum plates and low-quality aluminum plates is in terms of oxidation performance, tolerance, surface effect, crystal accuracy, and uniform stability. The difference in bending effect alone is not significant.

Advantage management and honesty as the foundation

Our products are exported to multiple countries and regions.

Please feel free to contact us

Sales Department 1: 0531-87885729 Manager Wang 15662708359 QQ: 1344074725

Manager Yin 0531-87886769 15064183919 QQ: 399298568

Sales Department 2: 0531-87869013 Manager Han 15564105123 QQ: 2929008953

Mobile station