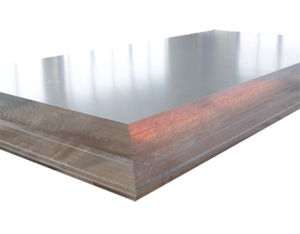

Aluminum waferFor users to cold extrude various specifications of capacitor shells, hoses, and aluminum shells, aluminum wafers are widely used in electronics, daily chemical, pharmaceutical, cultural and educational, and automotive accessories. Electrical appliances, insulation, mechanical manufacturing, automotive, aerospace, military, mold, construction, printing and other industries are sold to more than 40 countries and regions in Southeast Asia, Africa, Europe and America, Australia, and 31 provinces and cities across the country.

Method:

Punching machine processing: 1. Cutting of raw materials (cutting into squares) 2. Blanking~~~(punching into the round pieces you want)

If it is a coil material, add an uncoil at the front.

Fully automatic disc cutting processing: Fully automatic aluminum disc cutting is an integrated process that involves uncoiling coils, leveling the strip, disc cutting, finished product stacking, and waste cutting. Widely used in various types of aluminum wafer industries such as cooking utensils, lighting fixtures, and tank heads in the aluminum processing and manufacturing industry, it has met the large demand for wafer blanks for enterprises. Automatically select the most suitable layout method based on the width of the coil and the diameter of the disc, and directly perform material cutting processing on the entire coil strip, achieving a raw material utilization rate of over 80%, far superior to other disc cutting methods, and saving a lot of costs for enterprises.

The main components of the equipment include: uncoiler, leveling machine, feeding machine, swing unit, dedicated closed single point mechanical press, stacking device, waste cutting device, hydraulic system, electrical control system, etc.

Technical features:

1. CNC fully automatic, from the opening of the coil to the completion of all material cutting, there is no need for manual contact with any materials or adjustments, fundamentally eliminating the safety hazards and product quality hazards of ordinary punching.

2. This line can directly use coil material for wafer work, without the need for longitudinal and transverse cutting treatment of the coil material, reducing processes, costs, and the possibility of damaging the surface of the coil material.

3. This line fully utilizes the width of the coil material and adopts high-precision servo motor drive system control to minimize the distance between discs and the distance between discs and the edge of the material, fundamentally reducing the amount of waste and achieving a raw material utilization rate of over 80%.

4. The speed can reach 40-55 tablets per minute, improving efficiency.

5. Due to the modular mold design, the conversion time can be reduced to less than 15 minutes when converting wafer specifications. The diameter range of the disc ranges from 85 mm to 750 mm.

6. The advanced uncoiling system, six fold leveling machine, high rigidity mechanical press, automatic stacking system, etc. ensure the high quality of circular products.

Size:

From 0.02mm-50mm, with diameters ranging from 10mm-3000mm. Mainly determined by the purpose of the product.

Alloy state:

The majority are 1 series, 3 series, 5 series, 6 series, and 8 series.

The status is O, H * *, etc.